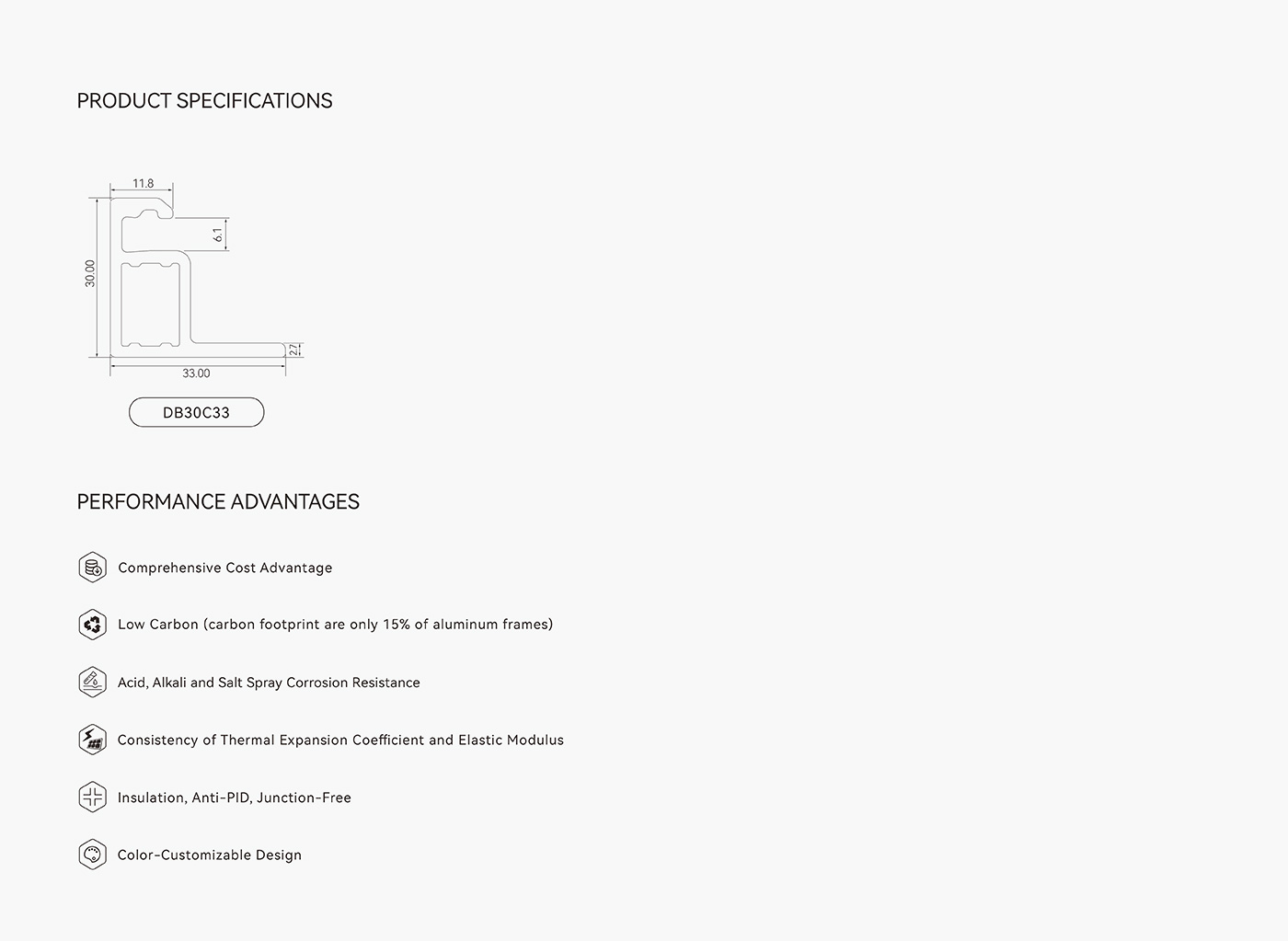

DB30C33

Nantong Aina New Energy Composite Photovoltaic Frame is a new type of frame material, mainly composed of polyurethane resin and glass fiber, produced through extrusion process. Having excellent mechanical properties, corrosion resistance, and insulation performance, while meeting the performance requirements of photovoltaic modules, it achieves module lightweighting, extremely low carbon emissions, and good cost-effectiveness, significantly reducing the risk of PID generation at the system end, and providing a good application solution for improving the quality and cost reduction of photovoltaic modules and ensuring stable operation at the system end

| Product Features | ||||

| Property | Aluminum Frame | Composite Material Frame | ||

| Mechanical Property | 250Mpa | 800~1200Mpa | ||

| Weather Resistance | Good Damp Heat Resistance Poor Salt Spray Corrosion Resistance |

Good Damp Heat Resistance, UV Resistance Salt Spray Acid and Alkali Corrosion Resistance |

||

| Carbon Emission | 15.8T | 0.23T | ||

| Insulation Property | Electric Conduction | Insulation and Free Grounding to Improve Safety of Operation and Maintenance | ||

| Density | 2.7g/cm3 | 2.1g/cm3 | ||

| PID | Conductivity, Easy to Generate PID | Insulation, No Electric Potential Difference, Excellent Anti-PID Performance | ||

| Thermal Expansion | 2-3 times that of glass | Consistent with glass | ||

| Electrochemical Corrosion | Easy to Cause Galvanic Corrosion | No Galvanic Corrosion | ||

| Basic Mechanical Behavior | ||||||

| Property | Referenced Standard | Unit | Standard Value-Wrapped Mat (2.1mm Thickness) |

Test Value-Wrapped Mat (2.1mm Thickness) |

||

| Density | ASTM D792 | g/cm3 | 2.05±0.1 | 2.1 | ||

| Longitudinal Tensile Strength | GB/T 1447 | MPa | ≥850 | 1020 | ||

| Longitudinal Tensile Modulus | GB/T 1447 | GPa | ≥40 | 49.4 | ||

| Longitudinal Flexural Strength | GB/T 1449 | MPa | ≥850 | 1586 | ||

| Longitudinal Flexural Modulus | GB/T 1449 | GPa | ≥40 | 35.4 | ||

| Volume Resistivity | GB/T 1410 | Ω·m |

≥1014 |

≥1014 | ||

| Flame Resistance | UL-94 | —— | V1 | V1 | ||

| Technical Parameters | ||||

| Property | Unit | Test Method | Technical Index | |

| General Requirements | Appearance | -- | Visualization | Smooth Appearance, No Cracks, No Scratches, No Fiber Leakage, No Obvious Bending or Bubbles |

| Color/Color Difference | -- | Visualization | As Per Customer Need | |

| Dimensional Deviation | -- | Vernier Scale, Tape Measure | As Per Drawings | |

| Physical Property | Longitudinal Tensile Strength | MPa | GB/T 1447 | ≥850 |

| Longitudinal Tensile Modulus | GPa | GB/T 1447 | ≥40 | |

| Longitudinal Flexural Strength | MPa | GB/T 1449 | ≥850 | |

| Longitudinal Flexural Modulus | GPa | GB/T 1449 | ≥40 | |

| Barcol Hardness | HBa | GB/T 3854 | ≥55 | |

| Straightness | mm/mm | Marble Platform | ≤1‰ | |

| Adhesion With Sealing | N/cm | --- | ≥90 | |

| Coating Adhesion | -- | Cross-Cut Test | Level 0 | |

| Bracket Pull Force | -- | --- | Load 20kg Weight for 1 Hour Without Falling | |

| Module Mechanical Load | -- |

Static Mechanical Load Test | Positive Pressure 5400Pa, Back Pressure 2400Pa | |

| Ultimate Back Pressure More Than5000Pa | ||||

| Physical Property After Aging | Longitudinal Flexural Strength | MPa | GB/T 1449 | ≥800 |

| UV300(200W/m2) | -- | IEC61215 GB/T1766 |

1. Appearance No Powdering, Yellowing, Cracking or Peeling. 2. Color Difference Compared to The Initial After Aging, Glossiness No Decreases 3. Mechanical Properties (Strength Modulus) Attenuation ≤5% |

|

| Insulation Property | Volume Resistivity | Ω·m | --- | ≥1014 |

| Breakdown Voltage | V | --- | ≥8000 | |

| Aging Characteristic Test (Double IEC) |

DH2000 | -- | IEC61215 | As Per Standard |

| High-Power UV300(800W/m2) | -- | IEC61215 | As Per Standard | |

| HF20 | -- | IEC61215 | As Per Standard | |

| TC200 | -- | IEC61215 | As Per Standard | |

| Salt Spray Test (Level 7) | -- | IEC61701 | As Per Standard | |